The Self-Drilling Screws or Self-tapping Screws for solar mounting are mainly used to fasten the roof brackets. The high-quality screws are used to secure roof brackets when attaching solar panels. These screws make assembly easier and faster.

Self-Drilling Screws For Wooden Beam And Steel Beam are essential components in solar installation systems, designed to provide a strong and reliable connection between installation brackets, beams, and other structural elements.

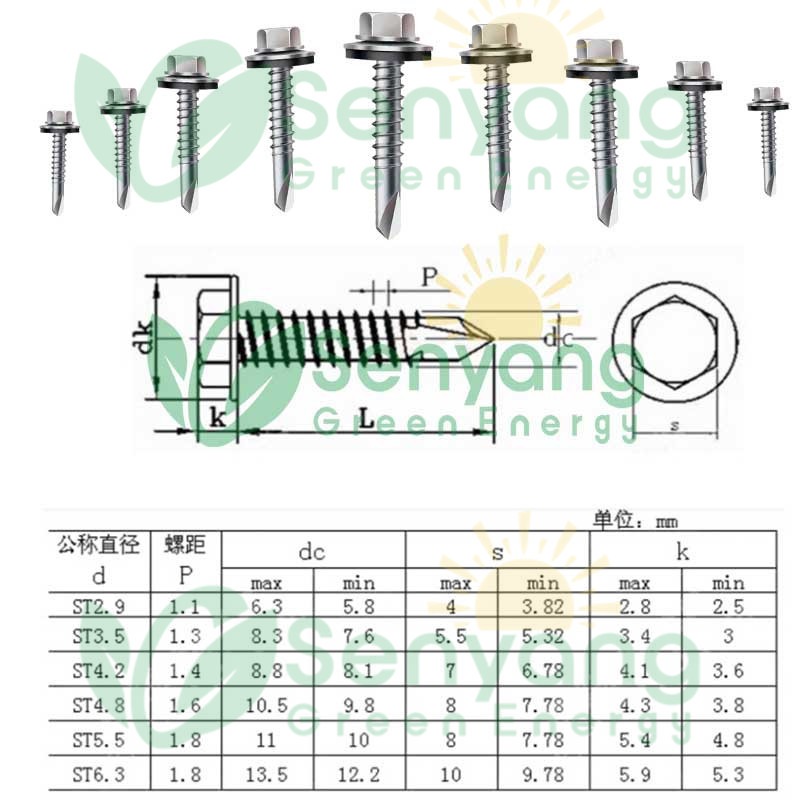

The main components of Hex Washer Head Self-Drilling Screws

Hex Washer Head (HWH):

High Torque Application: The internal hex (6-lobe) drive allows significantly higher torque application than Phillips or Torx drives. This is essential for driving the screw through thick steel or Wooden rafters without stripping the drive.

Integrated Washer: The built-in washer provides a large bearing surface. Distributes clamping force effectively. Helps seal the hole against water ingress (critical for rooftop longevity). And prevents the head from pulling through thinner sheet metal components. Acts as a lock washer against loosening (especially with serrated underside).

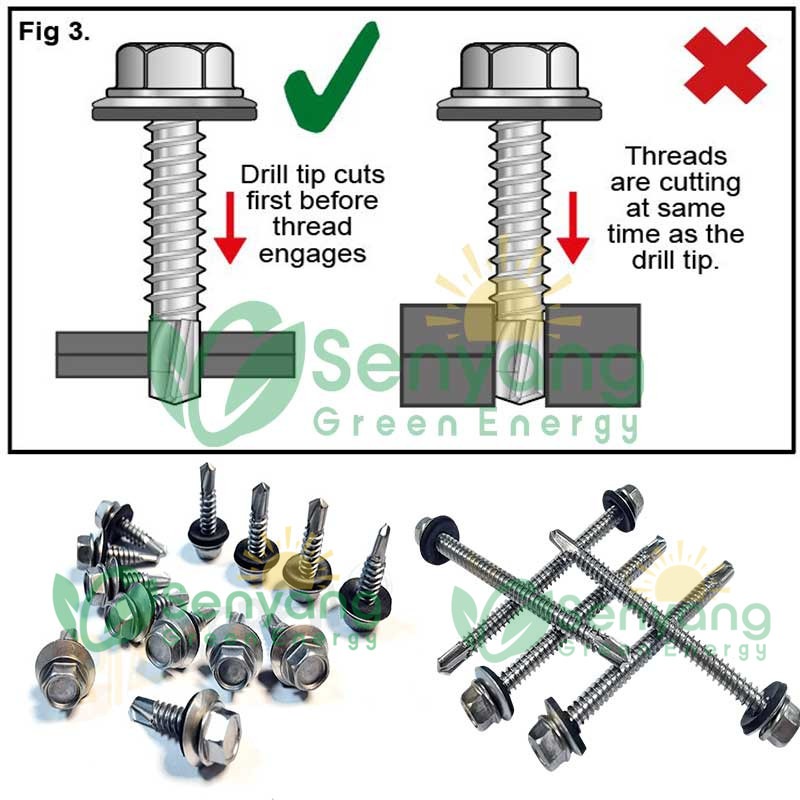

Self-Drilling Point: No Pre-Drilling Needed: The tip acts like a drill bit, creating its own pilot hole in the base metal (typically steel purlins, rafters, or rails). This dramatically speeds up installation and reduces labor costs.

Materials: Galvanized carbon steel or stainless steel, ensuring their strength and corrosion resistance.

We’re redefining the future of solar panel installations with our innovative Solar Self Drilling Screws. These remarkable screws are engineered to effortlessly pierce through various materials, making them the ultimate choice for securing solar panel mounting hardware. Discover how our self-drilling screws are transforming the solar industry.

Features of Hex Washer Head Self-Drilling Screws for Solar Mounting

- Cutting-Edge Self-Drilling Design:

Our Solar Self Drilling Screws feature a cutting-edge design that eliminates the need for pre-drilling holes. As they are driven into the surface, they create their own precise pilot holes, reducing installation time and effort.

- Superior Material Compatibility:

These screws are designed to excel in various materials, including metal, wood, and composite surfaces. Whether you’re mounting solar panels on rooftops or other structures, our screws offer unparalleled versatility.

- Unrivaled Holding Power:

Experience the confidence of a secure solar panel attachment. Our self-drilling screws provide unrivaled holding power, ensuring your panels stay firmly in place even in challenging weather conditions.

- Comprehensive Range:

Choose from our extensive range of Solar Self Drilling Screws, tailored to meet the diverse needs of your solar projects. Whether you’re working on residential or commercial installations, we have the right screw for the job.

- Efficiency and Precision:

These screws epitomize efficiency and precision. With no need for time-consuming pre-drilling, you can complete installations faster, reducing labor costs and project timelines.

- Durability Meets Sustainability:

We’re committed to sustainability, and our screws reflect this commitment. Crafted from high-quality, corrosion-resistant materials, they are built to withstand the test of time, contributing to the longevity of your solar installations.

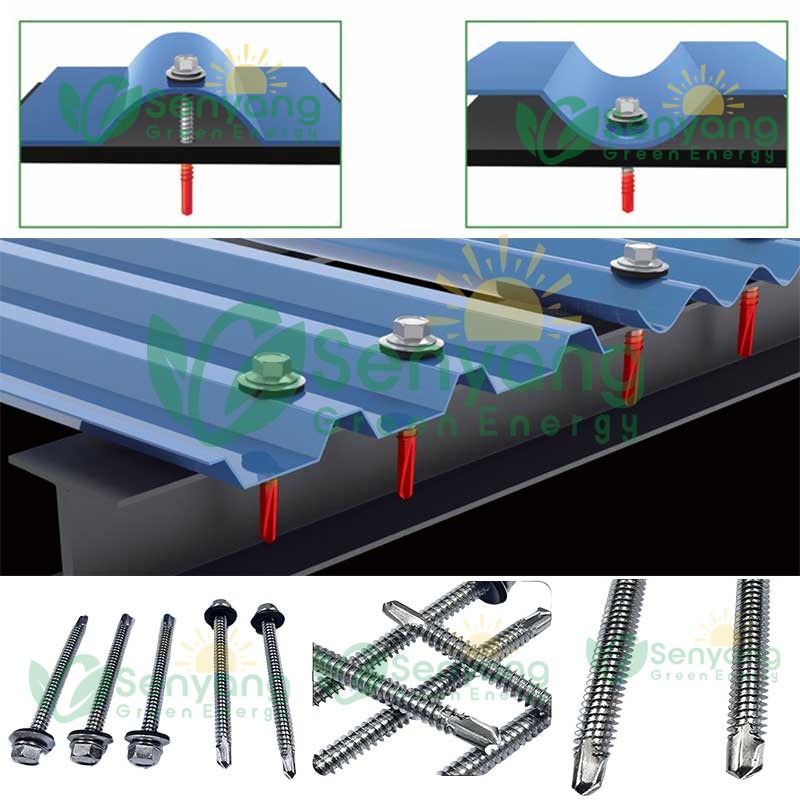

The Self-Drilling Screws for wooden beams and steel beams are normally used by our customers for all kinds of roofs, such as tile roof, metal tin roof, trapezoidal metal roofs and etc.The specifications of Self-Drilling Screws can be customized.

Solar industry professionals trust our Self-Drilling Screws for their unmatched quality and reliability. Join the ranks of satisfied customers who rely on our screws for successful solar projects.