Выбор подходящей винтовой сваи из оцинкованной стали для солнечных установок требует тщательного учета технических, экологических и специфических факторов проекта. Вот пошаговое руководство:

- Понять состояние почвы (самое важное!)

Тип почвы: Песчаная, глинистая, суглинок или каменистая? Для оценки используйте почвенный отчет или ручное тестирование (например, ручной шнек).

Несущая способность: Мягкие грунты требуют более длинных/тяжелых винтов; скалистые грунты могут потребовать специальных конструкций спиралей.

Уровень грунтовых вод и линия промерзания: Убедитесь, что сваи находятся ниже линии промерзания и избегайте зон подтопления, подверженных коррозии.

- Рассчитайте нагрузки на конструкцию

Вертикальная нагрузка: Вес панелей + монтажная конструкция + давление снега/ветра.

Боковая/подъемная нагрузка: Подъемные силы ветра (преобладают при солнечной активности). Для расчета ветровой/снежной нагрузки используйте ASCE 7 или местные нормы.

Запас прочности: Добавьте 25-50% для обеспечения безопасности (например, 5 000 фунтов на сваю при фактической нагрузке 3 500 фунтов).

- Технические характеристики свай

Диаметр и длина:

Обычные диаметры: 76 мм (3″), 89 мм (3,5″), 114 мм (4,5″).

Типичная длина: 1м-3м+ (глубже при неустойчивом грунте/высоких нагрузках).

Helix Design:

Односпиральный для стабильных почв.

Многоспиральные (2-4 лопасти) для слабых грунтов или высокой устойчивости к подъему.

Толщина вала: ≥4 мм для долговечности; ≥5 мм в местах, подверженных коррозии/высоким нагрузкам.

- Защита от коррозии

Гальванизация: Горячее оцинкованное (HDG) покрытие ≥80μm.

Дополнительная защита: Используйте цинк-алюминиевые покрытия (например, ZM-310) или полимерные рукава в сильно коррозийных почвах (pH 10, высокая соленость).

- Логистика проекта

Установочное оборудование: Подтвердите совместимость с гидравлическими приводами (например, требования к крутящему моменту: 2 000-6 000 Нм).

Сроки и поставки: Обеспечение своевременной поставки в соответствии с графиком проекта.

- Баланс между стоимостью и качеством

Избегайте занижения спецификаций для экономии средств - перегрузка чревата отказом системы.

Сравнивайте грузоподъемность $/кН, а не только стоимость за единицу.

Контрольный список быстрого выбора

Рекомендация по факторам

Тип почвы Тестируйте почву; многоспиральная спираль для слабых почв.

Грузоподъемность Включите 1,5-кратный коэффициент безопасности для ветра/снега.

Толщина покрытия ≥80 мкм HDG + экстра в жестких условиях эксплуатации.

Толщина вала ≥4 мм (стандарт); ≥5 мм (высокая нагрузка/коррозия).

Установка Контроль крутящего момента во время установки (проверка мощности).

Пример размеров

Эквивалент жилой крыши (10 кВт):

Сваи диаметром 76 мм-89 мм × 1,5 м-2 м (одновитковые, устойчивый грунт).

Коммерческий навес (100 кВт):

Сваи 89мм-114мм × 2,5м-3,5м (многоспиральные, глинистый грунт).

Когда следует обращаться к экспертам

Сложные участки: Скалистые грунты, склоны >10° или сейсмические зоны.

Крупные проекты: Для ферм коммунального назначения необходимы геотехнические изыскания и инженерные проекты.

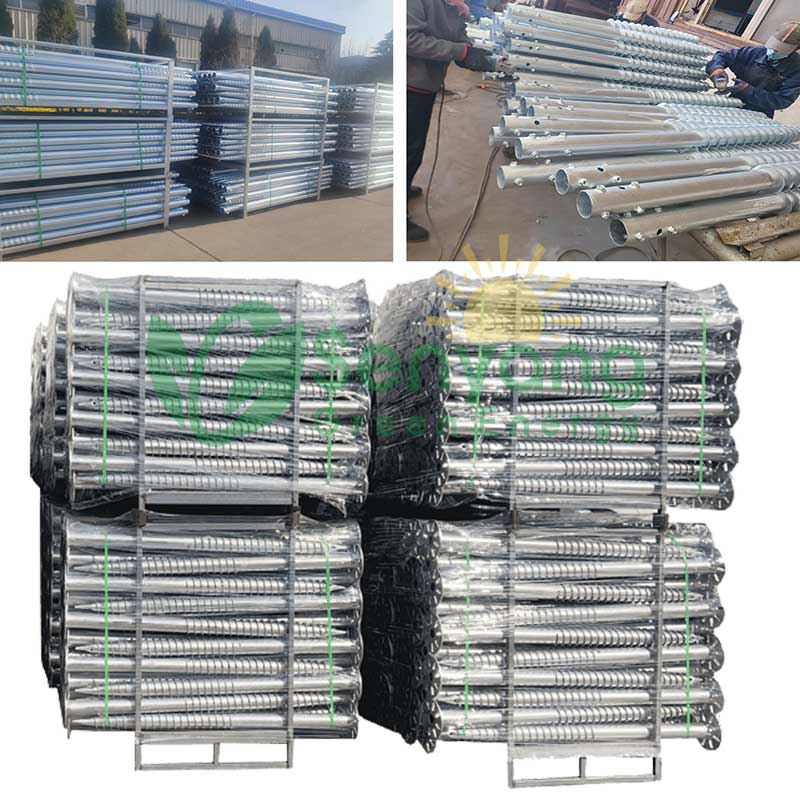

Наша компания разработала различные серии винтов для удовлетворения различных приложений. Фланец солнечной земли винты устанавливаются с рядом конкретных средств и машин, идеально перпендикулярно в точной точке после минут. В соответствии с практическими требованиями, солнечный монтаж грунт винтовые сваи могут быть запланированы и настроены на заводе, чтобы избежать сварки и вырезать на месте, экономя ваше время и стоимость.

Больше деталей для вас. Свяжитесь с нами по электронной почте:info@senyenergy.com

Interesting analysis!