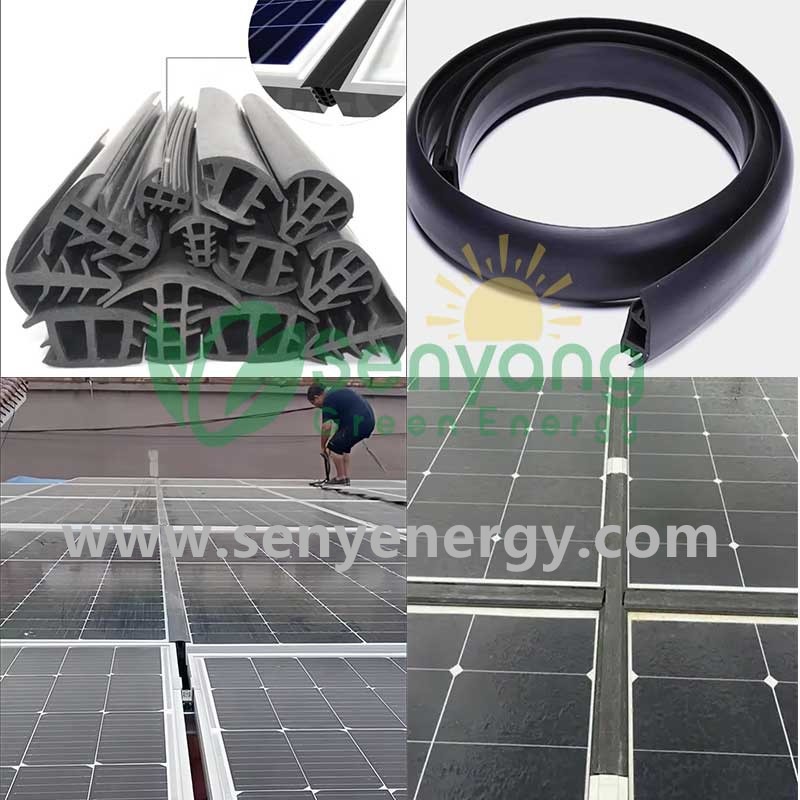

EPDM rubber gasket for solar panel is known for its excellent resistance to UV rays and high temperatures, making the seal suitable for use in all climatic conditions. Its flexibility allows for easy installation, adapting to different shapes and sizes of panels without compromising its sealing properties. This facilitates the installation process and reduces installation time.

Avantages de l'utilisation EPDM joint en caoutchouc pour solaire panneaux

L'utilisation de joints en caoutchouc EPDM dans les installations solaires ne protège pas seulement contre l'humidité, mais contribue également à augmenter l'efficacité énergétique. En empêchant la pénétration de l'eau et de la poussière, le joint aide à maintenir les performances optimales des panneaux et prolonge leur durée de vie. Cela se traduit par une réduction des coûts de maintenance et un meilleur retour sur investissement dans le système photovoltaïque.

The Challenge: Solar panels are installed outdoors and exposed to direct sunlight, rain, snow, hail, and temperature swings for 25+ years.

Why EPDM Excels: EPDM rubber gasket for solar panel has outstanding resistance to degradation from ultraviolet (UV) light and ozone. Unlike other rubbers that can become brittle, crack, and crumble under prolonged sun exposure, EPDM maintains its flexibility and sealing properties. This is arguably its most important advantage for solar applications.

2. Superior Temperature Tolerance

The Challenge: Solar panels can experience extreme temperatures, from freezing cold winters to scorching hot summers where the panel surface itself can exceed 85°C (185°F).

Why EPDM Excels: EPDM has a continuous service temperature range of approximately -40°C to +125°C (-40°F to +257°F). This means it won’t become brittle in a cold snap or melt and deform on a extremely hot day, ensuring a consistent seal year-round.

3. Excellent Water and Moisture Resistance

The Challenge: The primary job of the gasket is to create a watertight seal, protecting the panel’s frame, electrical connections, and mounting hardware from water ingress, which can cause corrosion and electrical failures.

Pourquoi EPDM rubber gasket for solar panel: EPDM is inherently hydrophobic (water-repelling) and has very low water absorption. It effectively seals out rain, snow, and humidity, preventing moisture from damaging critical components.

4. Good Chemical Resistance

The Challenge: Solar panels are exposed to environmental chemicals like acidic rain, salt spray (in coastal areas), and agricultural chemicals.

Pourquoi EPDM rubber gasket for solar panel: EPDM performs well against polar substances and mild acids and alkalis. It offers good resistance to salt water, making it a suitable choice for offshore and coastal solar farms.

5. Long-Term Durability and Elasticity

The Challenge: The gasket must maintain compression and not take a “set” over decades of use. It also needs to withstand minor structural movements and vibrations.

Pourquoi EPDM rubber gasket for solar panel: EPDM has excellent compression set resistance. This means that after being squashed between the aluminum frame and the mounting hardware for years, it will spring back and maintain sealing force instead of becoming permanently flattened and ineffective. Its inherent elasticity allows it to absorb vibrations and thermal expansion/contraction.

6. Electrical Insulation

The Challenge: While not its primary function, a non-conductive gasket provides an additional layer of safety by helping to electrically isolate the panel frame from the mounting rack.

Why EPDM Excels: EPDM is an excellent electrical insulator, adding a small but valuable safety benefit.

7. Cost-Effectiveness

The Challenge: Solar energy is a highly competitive market, and every component must offer value.

Silicone: Also has excellent temperature and UV resistance, often better than EPDM at the very high end. However, it is generally more expensive, has lower tear strength, and can be more easily damaged during installation. It’s often used for specialized, high-temperature applications.

PVC (Polyvinyl Chloride): Less expensive upfront but far inferior in long-term weather ability. PVC plasticizers can leach out over time, causing the material to become hard and brittle, leading to seal failure.

The choice of an EPDM rubber gasket for solar panels is driven by its proven track record of providing a durable, reliable, and cost-effective weather seal under the exact environmental challenges that solar installations face. Its unbeatable combination of UV resistance, temperature tolerance, and long-term elasticity makes it the default and rational choice for ensuring solar power system generate energy efficiently for their entire 25+ year lifespan. The gasket is available in 60 meter rolls, allowing flexibility in ordering according to the specific needs of the customer. Contact us to place an order or receive additional information about this product. Our team is ready to assist you with professional advice and guidance for optimal use of the rubber gasket in your solar installation.