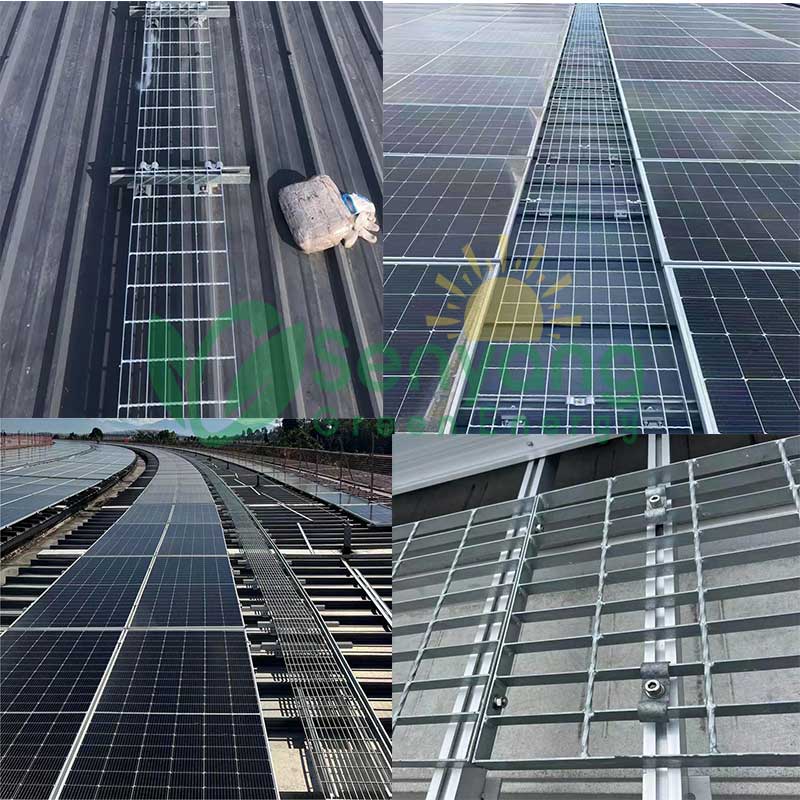

Anti-corrosif Passerelle solaire en caillebotis d'acier galvanisé à chaud est un élément d'infrastructure important dans les installations d'énergie solaire, en particulier pour les grandes fermes solaires. Il permet au personnel de maintenance de circuler en toute sécurité autour des panneaux solaires et des équipements. Fabriqué en acier à faible teneur en carbone, puis galvanisé à chaud, il offre une excellente résistance à la corrosion et une structure robuste, ce qui permet d'assurer un passage fiable pour les panneaux solaires. Il convient aux supports et accessoires solaires et constitue un élément clé des systèmes d'installation solaire sur les toits. Sa conception légère et ses caractéristiques de ventilation en font un choix idéal pour les bâtiments industriels, résidentiels et commerciaux, offrant une base fiable et un support durable pour les projets solaires.

Passerelle solaire en caillebotis d'acier galvanisé à chaud est idéal pour les bâtiments industriels, civils et commerciaux. Largement utilisé comme plates-formes, passerelles, marches d'escalier et planchers. Dimensions courantes : 2000*400*30mm. Combinés à nos pinces d'extrémité et à nos boulons et écrous en acier inoxydable, ils sont très faciles à installer sur le site. Possibilité de personnaliser les dimensions.

La couche de zinc protège l'acier de la rouille et de la corrosion et prolonge sa durée de vie. Le caillebotis galvanisé à chaud a une apparence métallique brillante et une structure légère. La conception à grille ouverte du caillebotis permet un drainage et une ventilation efficaces, réduisant l'accumulation d'eau et de débris. En outre, les propriétés antidérapantes du caillebotis garantissent une sécurité accrue. Il peut également être intégré à d'autres composants, tels que des ballasts, des supports ou des rails.

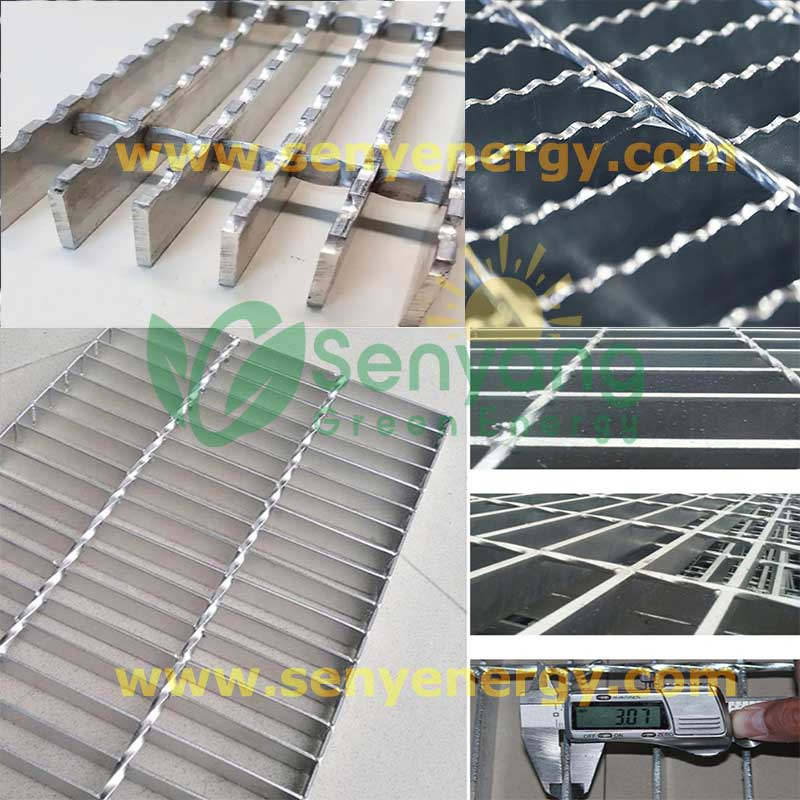

Spécification de la passerelle solaire en caillebotis d'acier galvanisé à chaud

Dimension : 2000 × 350 × 30 mm, ou 2000 × 500 × 30 mm

Matériaux : Acier au carbone

Traitement de surface : galvanisation à chaud (≥ 60 µm), norme ISO 1461 Zinc.

Barre porteuse : 30 mm Hauteur × 3 mm Épaisseur

Durée de vie plus longue que les passerelles en fibre de verre renforcée. Il est très facile de les installer sur place grâce à nos pinces d'extrémité et aux boulons et écrous en SS304.

Caractéristiques de la passerelle en caillebotis d'acier galvanisé à chaud:

Galvanisation à chaud : La passerelle est recouverte d'une couche de zinc par le biais du processus de galvanisation à chaud, ce qui lui confère une excellente résistance à la corrosion et une grande durabilité.

Construction robuste : Généralement fabriquée en acier galvanisé à chaud, elle est conçue pour résister à un trafic piétonnier intense et aux conditions environnementales.

Surface antidérapante : Une surface texturée ou perforée pour éviter de glisser, améliorant ainsi la sécurité lors de l'utilisation.

Conception modulaire : Disponible en différentes longueurs et largeurs, permettant des options d'agencement personnalisables pour répondre aux exigences spécifiques du site.

Avantages du caillebotis solaire en acier galvanisé à chaud :

Durabilité accrue : Le processus de galvanisation protège contre la rouille et la corrosion, garantissant une longue durée de vie même dans les environnements extérieurs difficiles.

Sécurité : Fournit une surface de marche stable et sûre, réduisant le risque d'accident pour le personnel d'entretien.

Facilité d'entretien : Les matériaux utilisés ne nécessitent qu'un entretien minimal au fil du temps.

Protection de l'environnement : Permet de minimiser le compactage et la perturbation du sol autour des installations solaires, favorisant ainsi de meilleures pratiques environnementales.

Conclusion

A Passerelle solaire en caillebotis d'acier galvanisé à chaud est essentiel pour assurer un accès sûr et efficace aux installations solaires. Sa durabilité et sa résistance à la corrosion en font un choix idéal pour les environnements extérieurs, améliorant la sécurité et l'accessibilité globales des systèmes d'énergie solaire. Si vous avez d'autres questions ou si vous avez besoin de recommandations spécifiques, n'hésitez pas à nous contacter !